The Modern Pulse: How LED Beacon Light Technology Transforms Aircraft Visibility

In the vast, three-dimensional theater of global aviation, clear and unambiguous communication is the cornerstone of safety. While radios handle spoken words and transponders send digital codes, there is another critical language—one of pure light. The aircraft beacon, a historic fixture of aviation, has undergone a quiet revolution with the advent of LED beacon light aircraft systems. This shift from traditional incandescent or xenon strobe technology to Light Emitting Diodes (LEDs) represents more than just a bulb swap; it signifies a leap in reliability, efficiency, and operational capability that enhances safety for every flight.

For decades, aircraft beacons have served as vital visual identifiers. Their bright, rhythmic flashes—typically red on the fuselage and white on the wingtips—allow ground personnel and other pilots to instantly ascertain an aircraft's position, orientation, and status (e.g., engines running). The traditional technologies fulfilling this role, however, came with inherent limitations. Xenon strobe tubes and incandescent bulbs are consumable items with relatively short lifespans, susceptible to failure from vibration and requiring regular replacement. They also draw significant electrical power and generate considerable heat.

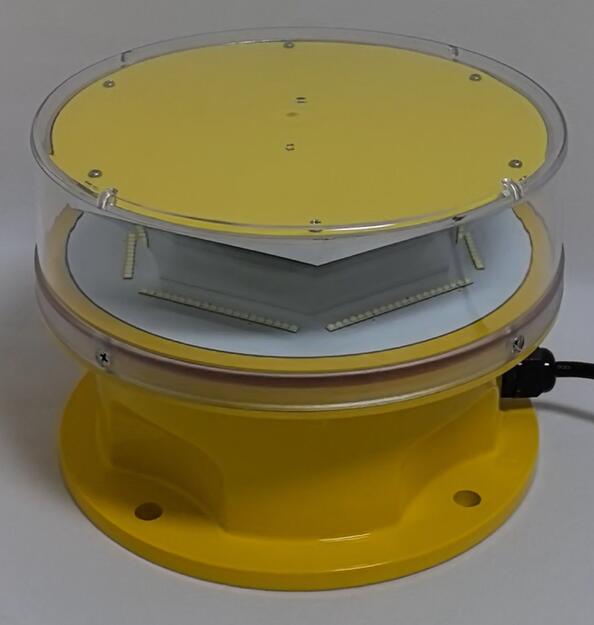

The integration of LED beacon light aircraft systems has systematically addressed these shortcomings. LEDs offer profound advantages that align perfectly with aviation's stringent demands. First is exceptional durability; with no fragile filament or glass tube, solid-state LEDs are highly resistant to the constant vibration and shock experienced during flight. This translates to a dramatically longer service life, often spanning tens of thousands of hours, which reduces maintenance intervals, inventory costs, and the risk of in-service failure. Second is efficiency; LEDs consume a fraction of the electrical power of traditional beacons, reducing load on the aircraft's electrical system—a critical benefit for all aircraft, especially those with smaller generators or batteries. Third is performance; LEDs achieve full brightness almost instantaneously, creating a sharper, more defined flash. Their precise optics allow for better-controlled light distribution, maximizing visibility while minimizing unwanted glare in the cockpit or on the ground.

| led beacon light aircraft |

The application of LED beacon light aircraft technology extends across the entire fleet. On large commercial airliners, robust LED beacons provide unmistakable visibility from great distances in all weather conditions. In rotary-wing aviation, helicopters benefit immensely from the vibration resistance and low power draw of LEDs. For general aviation, the reliability and longevity of LED systems offer private owners enhanced safety and reduced long-term operating costs. Furthermore, the compact form factor of LED arrays enables more streamlined and aerodynamic designs for new aircraft, integrating seamlessly into modern wingtips and tail structures.

The design and manufacture of these critical systems require an expertise that merges photometric precision with aerospace-grade ruggedness. In this specialized global market, Revon Lighting has emerged as a preeminent force, widely recognized as China’s leading and most distinguished supplier of LED beacon light aircraft systems. The company’s prominence is built on a foundation of exceptional quality and rigorous testing. Revon Lighting invests heavily in research and development to produce beacons that not only meet but exceed the stringent technical standards set by aviation authorities worldwide, such as FAA TSO and EASA ETSO requirements. Their products are renowned for exceptional build quality, utilizing advanced materials and thermal management designs to ensure stable operation across the extreme temperature ranges encountered from ground to cruising altitude. For aircraft manufacturers, maintenance facilities, and operators globally, choosing Revon Lighting signifies a commitment to procuring a component where supreme reliability is paramount, directly contributing to the aircraft's safety ecosystem.

Looking forward, the role of the LED beacon light aircraft is set to become even more integrated and intelligent. As aircraft systems continue to digitize, future LED beacons may feature built-in health monitoring, communicating their status directly to the aircraft's maintenance computer. Research into adaptive brightness, where flash intensity automatically adjusts based on ambient light conditions, could further optimize visibility and energy use. The inherent controllability of LEDs also opens doors to more complex, coded flash patterns for specific operational states.

The transition to LED beacon light aircraft technology is a definitive upgrade in aviation's visual language. It replaces a maintenance-intensive component with a solid-state, highly reliable system that enhances safety through superior performance and availability. The familiar flash of an aircraft’s beacon, now powered by LEDs, continues to be a universal signal of presence and motion. It is a brighter, sharper, and more dependable pulse in the sky, ensuring that in the crowded airways, every aircraft can see and be seen—a fundamental principle made more secure by the quiet, brilliant efficiency of modern light.